By: Eric Johnson

Hello. My name is Eric and I work for Professor Smaranda Marinescu in the Chemistry Department at USC. Our group focuses on developing compounds that can be used for alternative energy purposes in order to combat global warming. One of the ways people have started trying to fight climate change is by using fuel cells instead of combustion engines in cars. Currently, fossil fuels in the form of gasoline are pumped into your car and combusted to produce energy, but the carbon dioxide emissions from this process have been leading to negative environmental side effects. Instead, fuel cells are being designed to run based on water.

In these fuel cells, hydrogen gas (H2) is used as a source of energy and water is generated throughout the reaction. Scientists have made a lot of progress on the hydrogen to energy step of this process, but using oxygen gas (O2) to make water is a much more complex issue. This process is referred to as the Oxygen Reduction Reaction (ORR) and is what I work on in my group, and the focus of my summer research as a WIES Sonosky Fellow.

One proposed method of making ORR easier is to use catalytic materials to promote the reaction. Catalysts are materials that make the reaction easier without being consumed, so they can help perform the same reaction repeatedly over a large amount of time. In our group, we prepare catalysts for ORR in a couple of different ways. One set of catalysts are made thermally, which just means we combine all the parts in the same container and heat them to high temperatures to cause a reaction. This reaction deals with starting materials that are not very reactive with each other so they need a push from heat energy.

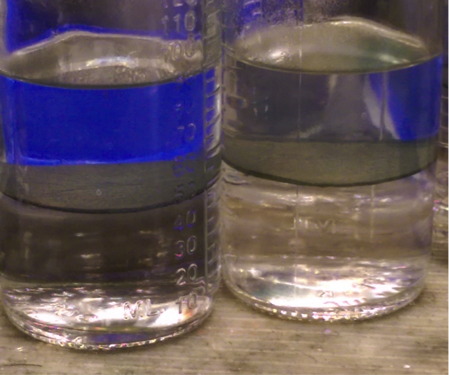

The other material does not have this problem, and is actually too reactive. If left on their own, these materials react too rapidly and form a mess instead of the nice catalyst that we want, so we use a layering method to slow down the reaction (see the photo above). In the same way oil floats on top of water, certain chemical solvents will not mix with water. We use this principle to separate the two reacting chemicals: one chemical in water and one in the “oil”. These solutions only touch slightly, but that little bit of touching is enough to allow for a slow and controlled reaction at the interface to give us our active catalyst.

Once the catalysts are made, we can subject them to the conditions they would encounter if they were used in a fuel cell and evaluate how they hold up to leading standards. We hope to develop catalysts which can help make fuel cells a viable replacement for combustion engines both energetically and also economically. If we can do this, the impact of global warming can be lessened and we can have a cleaner, cooler world.